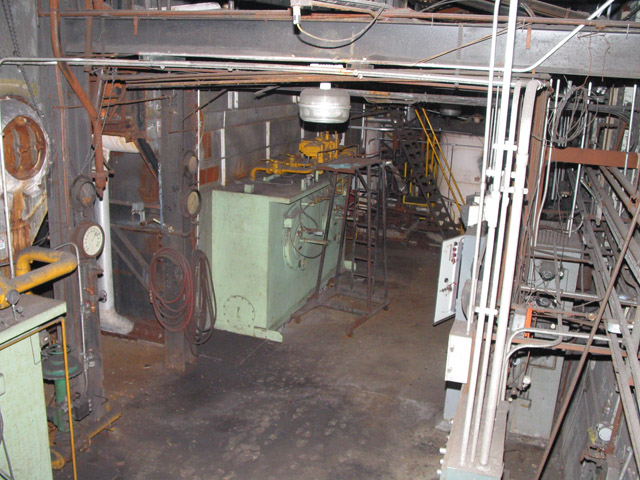

Here is one of the gas boilers as seen from the door to the coal bunker.

GP Kalamazoo Mill - Powerhouse and Coal Bunker: Boiler Room

Alliedpaper.org Home / GP Kalamazoo Mill / Powerhouse and Coal Bunker

Coal Bunker * Boiler Room * Turbine Room

As far as we could tell, the boiler room of the Georgia Pacific Kalamazoo Mill contains three natural gas fired boilers and one coal-fired boiler. The coal fired boiler looked a lot bigger than the gas units, but it is hard to say for sure.

Here is one of the gas boilers as seen from the door to the coal bunker.

Here's another one. The gas powered boilers in this plant seem to have two sets of burners each.

In the foreground is the coal boiler and in the background is the third gas boiler. I am not sure what kind of coal feed system this boiler used. From the looks of it, I would say that it either grinds the coal into dust and blows it into the furnace with air (almost like a gas or oil burner), or perhaps it grinds the coal into fine pieces and conveys them into the furnace on a belt. Either system is more efficient than simply conveying chunks of coal into the furnace, but I do not know the pros and cons of powder vs. crushed.

Here is a burner on one of the gas-fired boilers. Given the rather large diameter of the rest of the gas pipes in the building, I wonder why the pipe in this picture that appears to convey the gas into the actual burner is so small...

Maybe the apparatus between the large gas line and the burner line compresses the gas to an extremely high pressure? It seems like you would sure need a LOT of pressure, though, to squeeze as much gas as could flow through the large pipe at nominal service pressure into that tiny flex pipe...

Here's a closer look at the coal feeding apparatus.

Evidently it, or at least part of it, is made by Westinghouse.

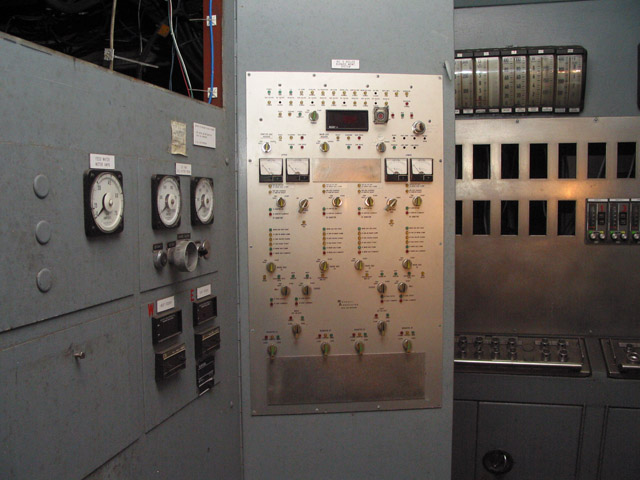

Here's a control panel for one of the boilers; probably one of the gas units. This panel is right in the boiler room, across the aisle from one of the boilers.

A small room to the side of the boilers contains what appears to be the main boiler control panels and indicators.

The control room has a couple of chart recorders and some warning lights, but seems quite sparsely appointed. It also seems rather low-tech; not a single computer is to be found.

This printer produced a log of what went on with the boilers and related systems.

On the other side of the boiler room, there is a piece of equipment that looks like it is involved in the treatment or preheating of feedwater.

There is a colorful and odd-looking grotto off the boiler room area.

These stairs go up, up, up the boiler ahead.

One can go underneath the boilers in this plant. I think that this is the bottom of the coal-fired unit.

I suppose that they would use these doors to remove ashes, but I wonder what the little chutes are for.

Here is the incoming natural gas line and shutoff valve for the entire power plant.

There are many pumps and pipes in the basement next to the boilers.

There are also many valves.

Continue on to the Turbine Room